Laser cutting of metal

-Laser cutting is one of the most advanced technologies for working with sheet metal. It allows you to produce geometrically complex parts with maximum accuracy, while minimizing impact on the material and leaving a minimum of waste.

-Laser cutting is suitable for most metals and alloys. Especially laser cutting services are effective for cutting sheets up to 6mm thick from easily deformed and soft materials.

-The power of the laser beam is regulated depending on the properties of the cut metal, thickness and contour. The result is a flawlessly smooth, dross-free surface that does not require additional processing when cut.

-Compared to plasma cutting, the laser method provides narrower cuts and precise edges. By focusing the laser beam, only a narrow area of the material is heated, which reduces the appearance of deformations during processing. Higher accuracy is achieved when cutting small parts of complex configuration.

Video of laser cutting metal:

Photo of the laser machine:

Laser cutting of metal to order

We offer a wide range of services for high-quality metal processing in Kiev, and laser cutting is one of the most important and most demanded among them for many reasons. Certain types of repair and construction work in modern conditions require fast and high-precision metalworking, which is why this type of service is so relevant.

- Extremely high precision for cutting metal of almost any alloy;

- Ability to process metal along the contour of any, the most complex shape;

- No need to clean the finished product - the laser does not leave uneven edges or burrs on the metal;

- Brothers can wind up new workpieces, fragments during laser deformation of metal into the casing.

Metal laser cutting services

We offer a wide range of services for high-quality metal processing in Kiev, and laser cutting is one of the most important and most demanded among them for many reasons. Certain types of repair and construction work in modern conditions require fast and high-precision metalworking, which is why this type of service is so relevant.

- Our company has modern equipment for the prompt and efficient execution of tasks related to metal cutting;

- The high speed of this modern high-precision equipment allows our employees to perform high-quality cutting of metal sheets of small thickness;

- The specialists working with us have not only high professionalism and specialized education, but also extensive experience in this particular service sector;

- The variety of tasks performed by our company allows our clients to save money and time by ordering a full range of metalworking services in one place;

- The quality of our work meets the highest requirements for the modern service market;

- The shortest possible terms of order execution, work with customer's sketches, exact fulfillment of obligations under the contract - you can trust us!

Our equipment:

For laser cutting we use a high-precision AMARIS laser machine.

- The size of the work surface of the table is 1500 × 3000 mm;

- Maximum sheet thickness is 16 mm;

- High precision cutting - positioning accuracy at coordinates + -0.01 mm. This allows you to create the most complex parts and minimize waste;

- Parts have a clean and smooth cut without burrs and burns;

- Ability to laser cut sheet metal: black, galvanized, stainless, aluminum.

Material requirements:

- Flat sheet;

- Maximum sheet size 1500 X 3000 mm;

- The sheet is clean without corrosion;

Drawing requirements:

- Vector layout in CorellDraw (up to X6), AutoCAD (up to 2009);

- Scale 1: 1;

- Dimensions in mm;

- No double lines, intersections, should not contain open lines, fills, overlays, object locks;

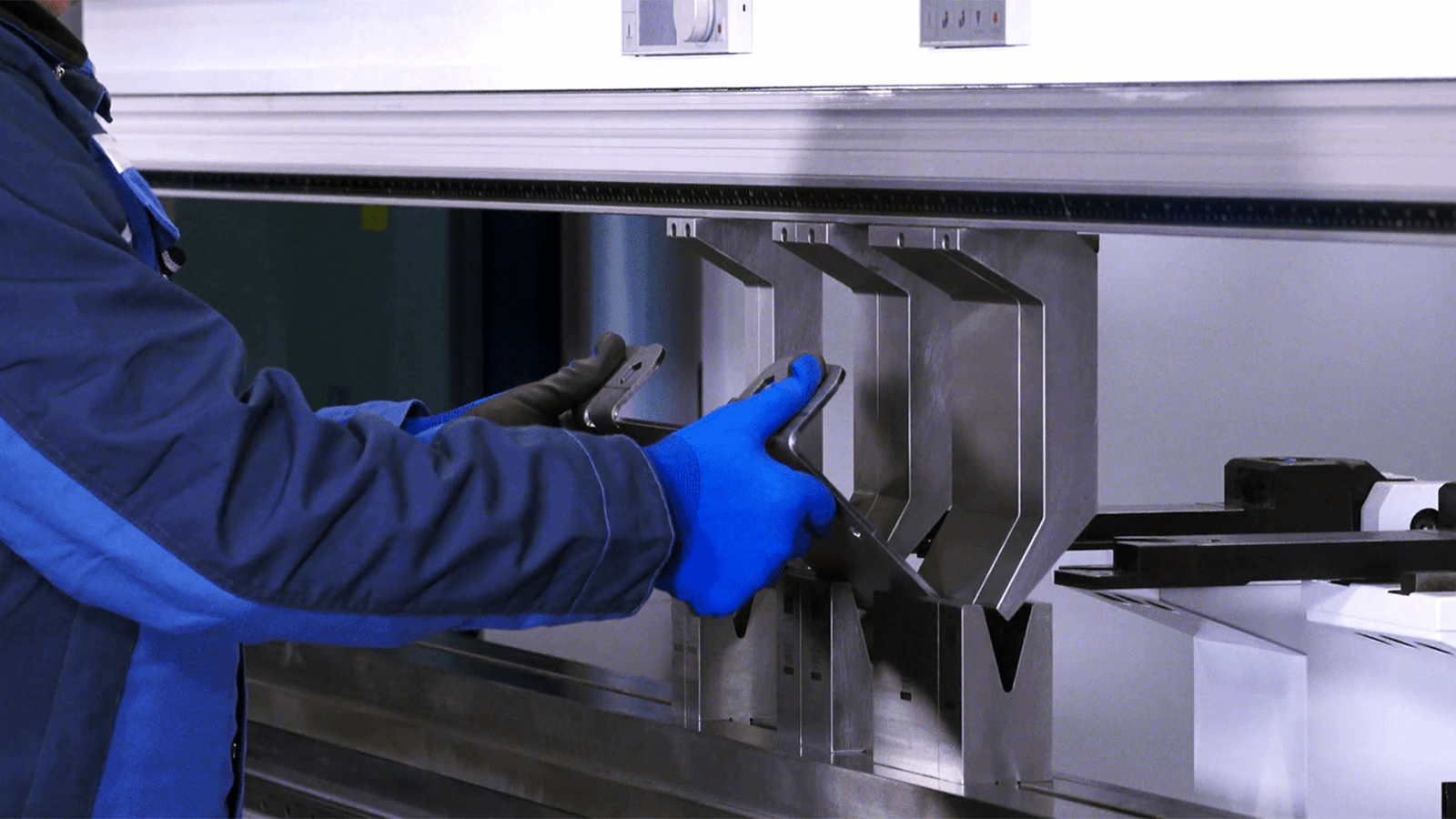

Sheet metal bending

-Metal bending on CNC machines is a modern technology of metal deformation processing, which makes it possible to produce strong and complex structures without the use of additional equipment.

-Metal bending in Kiev is needed in the production of channels, angles and other types of profiles. In this way, not only planes bent at the desired angle are obtained, but also curved edges.

-Bending sheet metal on CNC machines allows you to bend parts as accurately and with perfect repeatability. The quick-release tool makes it possible to perform a sequence of several actions, producing profiles of various configurations.

-If it is necessary to bend parts with large radii, the surface will be a collection of small edges. The production of parts with oblique shelves is possible.

Bending metal to order

By contacting our company, you will receive a full range of services, because we are bending metal using modern equipment produced by the world's leading manufacturers:

- Calculation of the parameters of the blank and the final product will be performed by our specialists. If necessary, employees will help in the development of drawings of the part;

- The metal bending carried out by us in Kiev is carried out quickly, the quality of work is guaranteed. These factors have a positive effect on the cost of production. And most importantly, the customer is relieved of the need to spend money on the purchase of expensive complex equipment;

- The price for metal bending performed by the company is affordable. Our employees will carry out a preliminary calculation of the cost of work and will support the project until its completion;

Powder coating of products

Powder coating of metal products has become widespread due to the fact that it provides a high quality coating, retains excellent physical, chemical and finishing characteristics. One coat is sufficient for even and dense coloring of parts. We carry out polyester powder coating, we use high quality tested paints. We follow every stage of the powder coating technology.

Powder coating services to order

Take into account the fact that in addition to painting metal products, the company is also engaged in metalworking. So, with only drawings in hand, we can create and paint a product of any shape for you. Thanks to our own equipment and the professional skills of our staff:

- Painting any metal products that can withstand temperatures up to 200 ºС;

- Custom painting of exclusive metal products (cornices, racks, railings, fences, booths, gazebos, elevator frames, doors, etc.)

How is powder painting done

The powder coating process consists of three important steps:

- surface preparation;

- powder coating;

- polymerization - baking under the influence of high temperature (up to 250 ºС);

Full cycle of welding works

Our welders are professionals in their field. During the work of the company, we have completed many different orders and accumulated vast experience. When performing welding work, we focus on the quality that our customers appreciate, and we guarantee a high level of work performed. Therefore, we pay special attention to an individual approach to the customer.

Our production:

Our company has a powerful welding workshop. The workshop is equipped with ten Swan tables with welding equipment and, in turn, is provided with first-class specialists. All this allows us to satisfy the wishes of even the most demanding client:

- We offer a wide range of welding works performed by us. These can be solutions for the improvement of the territory of suburban areas and cottages (decor elements). In particular, metal gazebos for protection from precipitation or bright sun, solutions for outdoor recreation (barbecues) carports, gates and fences as elements of a country cottage; metal canopies for the arrangement of building facades.

The order for welding works is formed depending on the complexity. Just call us and our managers will offer you an extremely attractive offer!

Welding work with metal structures is a rather complicated procedure, where strict adherence to production technology is required. After all, it is the quality and compliance with the deadlines for the execution of the order that is the key to the success of our company. design efficiency during operation and service life. Therefore, we recommend that you contact the professionals of our company. They won't let you down!

- Our company has modern equipment for the prompt and efficient execution of tasks related to metal cutting;

- The high speed of operation of this modern high-precision equipment allows our employees to perform high-quality cutting of metal sheets of small thickness;

- The specialists working with us have not only high professionalism and specialized education, but also extensive experience in this particular service sector;

- The variety of tasks performed by our company allows our clients to save money and time by ordering a full range of metalworking services in one place;

- The quality of our work meets the highest requirements for the modern service market;

- The shortest possible terms of order execution, work with customer's sketches, exact fulfillment of contractual obligations - you can trust us!

Design development

Highly qualified specialists of the company with significant experience in the development of case products, brackets and other metalworking services of various levels of complexity, etc., will quickly and efficiently develop and design various types of products according to your specifications or sample. The existing automation and computerization system allows you to significantly reduce the preparation time for production, and an individual approach to the customer allows us to take into account all your requirements and wishes.

Specialists of our company will help you develop design documentation for metal products, convert electronic drawings, convert paper drawings into electronic form, and provide the necessary technical advice. The high professionalism of our employees, plus high-tech equipment using the latest generation tools, allows us to produce products of the highest quality and at a flexible price system. The cost of work is determined individually, depending on the level of complexity.

Development of design documentation and custom products

- New product design;

- Development of design documentation (ESKD);

- Drawings according to DIN, ISO, ANSI standards;

- Create 3D models.

Our advantages

- All work is carried out by professional design engineers;

- We provide a full design cycle from conceptual design to the release of a complete set of design documentation for a product and production of prototypes;

- Development of drawings both according to the Russian ESKD standard, and according to foreign ISO, DIN standards;

- Efficiency of work;

- Possibility to go to the site for measurements;

- Individual approach to each order;

- Reasonable prices, discounts for regular customers;

- High quality design work.